Screw a Bolt into a Nut¶

This tutorial showcases how to set up and use PolyFEM to simulate screwing a bolt into a nut (for example, to be used in a robotic assembly simulation).

Prerequisites¶

In this tutorial, we assume you have already installed PolyFEM on your machine. If not, please follow the instructions here. After compilation, to use PolyFEM in any working directory machine, we can set up an alias for the main executable for ./PolyFEM_bin by adding the following to ~/.bashrc or ~/.zshrc according to the type of your shell.

alias polyfem='path/to/PolyFEM/build/PolyFEM_bin'

Then you can use it by

polyfem --help

Data Preparation¶

The data needed in this tutorial can be found here. The volume mesh files are all made by fTetWild. Feel free you make your screws and nuts.

Overview¶

In these tutorials, the bolt will be screwed into the nut in several different ways. The tutorials can also be found at Github: Screw tutorials. The screw is represented as a volume mesh

"geometry": [{

"mesh": "data/screw-big.msh",

"transformation": {

"translation": [0, 0, 0],

"scale": 0.01

},

"volume_selection": 1,

"surface_selection": 2

}]

and the nut is set to be an obstacle just to speed up the simulation by setting "is_obstacle": true because obstacles in PolyFEM are rigid and only the surface of obstacles is taken into consideration.

"geometry": [{

// ...

}, {

"mesh": "data/nut-big.stl",

"is_obstacle": true,

"transformation": {

"translation": [0, -0.02675, 0],

"scale": 0.01

}

}]

For other parameters, the bolt is using the parameter of steel

"materials": [{

"type": "NeoHookean",

"id": 1,

"E": 2e11,

"nu": 0.3,

"rho": 8050

}]

Fully Constrained Screw in All Dimensions¶

In this tutorial, the screw is completely controlled by Dirichlet boundary conditions in all three dimensions. Thus the trajectory of the screw is fixed(rotation and transformation) and needs to be calculated carefully. For a single-threaded bolt and every rotation of \(360^{\circ}\), the bolt will go into the nut by the thread distance. In this case, the thread distance of the screw used in this tutorial is 1.33m. Therefore the Dirichlet Boundary Condition is set to

"dirichlet_boundary": [{

"id": 2,

"value": [

"x*cos(-2*pi*t) + z * sin(-2*pi*t)-x",

"-1.33*0.01*t",

"-1*x*sin(-2*pi*t) + z * cos(-2*pi*t)-z"

],

"dimension": [true, true, true]

}]

Here the angular velocity of the rotation is \(-2\pi\) and the bolt is getting into the nut along the y-axis by \(1.33\times 0.01\) since the bolt and the nut is scaled by 0.01. The "dimension" argument is set to be true for all three dimensions to make sure the bolt is in full control.

To view the whole JSON file for this case, please go to screw.json.

To run this JSON with PolyFEM, please go to the GitHub repo Github: Screw tutorials and run the following in your terminal

polyfem --json screws.json --output_dir results

Constrained Rotation but Free Movement in the Direction of Feed¶

In this tutorial, only two dimensions have Dirichlet boundary conditions. For the y-axis or the direction of feed, the screw is completely free. Therefore we only need to specify the rotation in the Dirichlet boundary condition and the bolt would get into the nut by basic high school physics.

"dirichlet_boundary": [{

"id": 2,

"value": [

"x*cos(-2*pi*t) + z * sin(-2*pi*t)-x",

"-1.33*0.01*t",

"-1*x*sin(-2*pi*t) + z * cos(-2*pi*t)-z"

],

"dimension": [true, false, true]

}]

The only thing we need to modify in the "dirichlet_boundary" argument is to change the y-axis in "dimension" to false.

Top Constrained Bolt¶

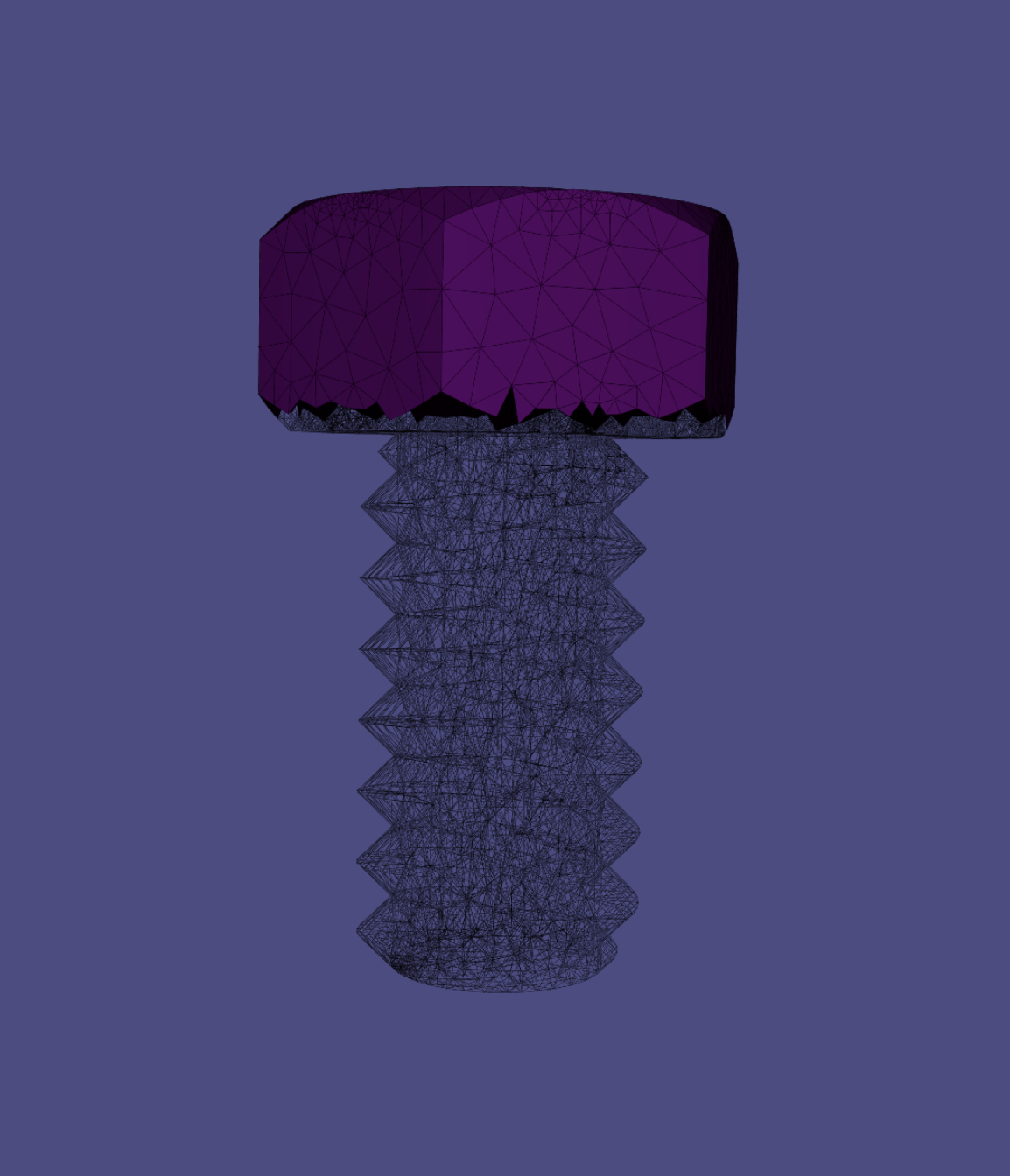

Instead of putting Dirichlet boundary conditions on the whole bolt, we can also constrain only the top of the bolt to simulate some actuators. The following image is the visualization of the bolt only constrained on the top of the bolt by Dirichlet boundary conditions.

To make specified boundary condition selections, please refer to Selections. In the JSON file, we need to change the surface_selection to the axis-plane selection method instead of using an integer to select the whole body of the bolt.

"geometry": [{

"mesh": "data/screw-big.msh",

"transformation": {

"translation": [0, 0, 0],

"scale": 0.01

},

"volume_selection": 1,

"surface_selection": [{

"id": 3,

"axis": "y",

"position": 0.11

}]

}]

which is to apply the boundary condition with id=3 to the meshes whose coordinates in the y-axis are greater than 0.11 (If set "axis": "-y" is to select the negative side of the y-axis which are the meshes whose y-coordinates are less then 0.11).

To view the whole JSON file for this, please go to top_constrained.json.

Two Facets Constrained Bolt¶

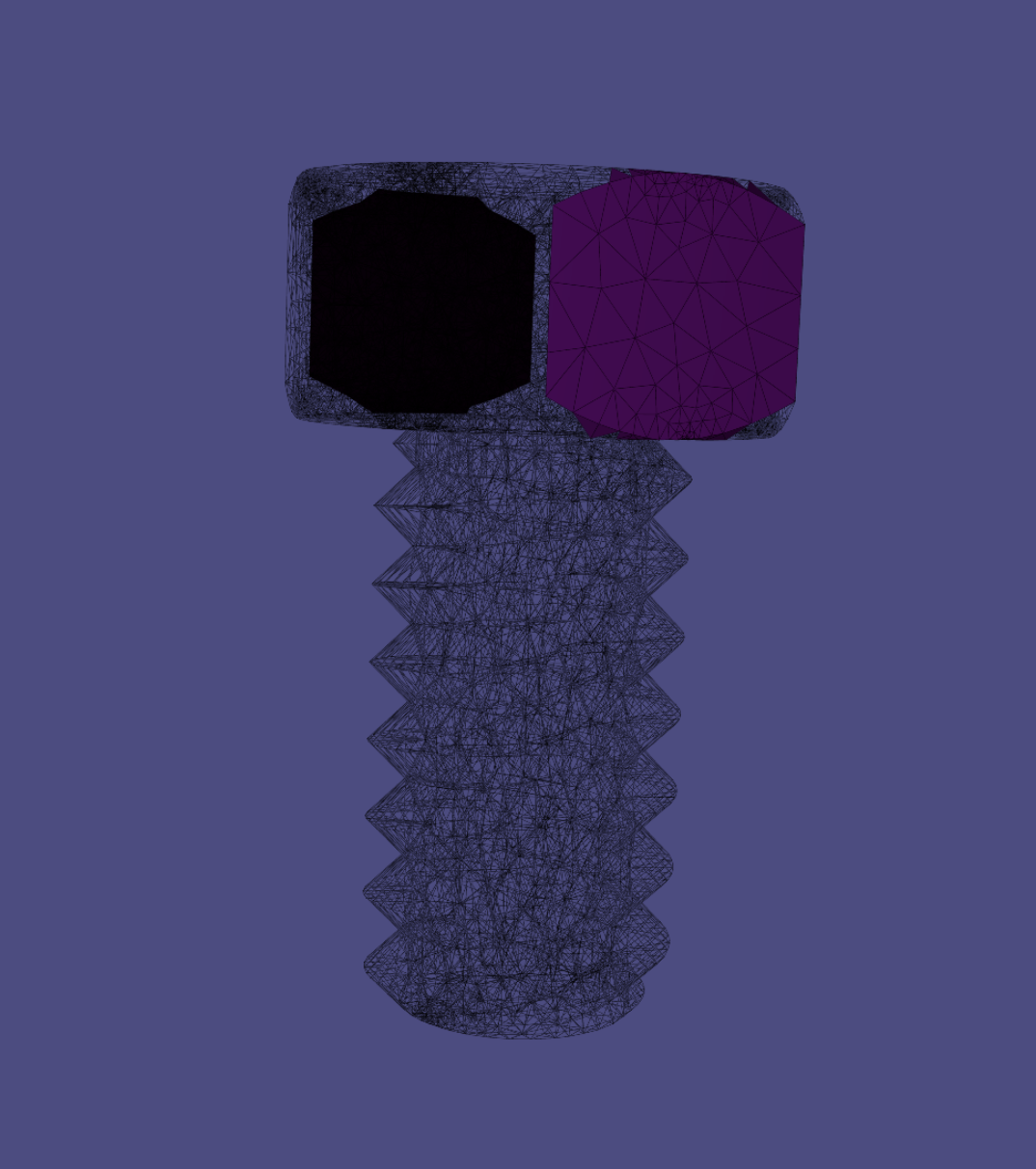

In addition to constraining the top part of the bolt to simulate an actuator, we can also only constrain the two facets of the head of the bolt to simulate a user pinching the bolt with two fingers and trying to screw the bolt into the nut. The following image is the visulization of contraining just two facets of the bolt.

In this case, the "boundary_sidesets" becomes:

"boundary_sidesets": [{

"id": 2,

"axis": -3,

"position": -0.039

}, {

"id": 2,

"axis": 3,

"position": 0.039

}]

To view the whole JSON file, please go to two_facets_contrained.json.

Gravity Controlled Bolt¶

In theory, if the friction is 0 and the gravity is the only force applied to the bolt, then the bolt should be able to get into the nut automatically under gravity. In this case, it is not very useful but it is interesting to test. There’s no need to set any boundary conditions because the bolt is completely free. The only thing that needs to be done is to enable gravity in the JSON file by setting

"boundary_conditions": {

"rhs": [0, 9.81, 0]

},

Note that the direction of gravity is along the y-axis.

The whole JSON file is here only_gravity.json.